|

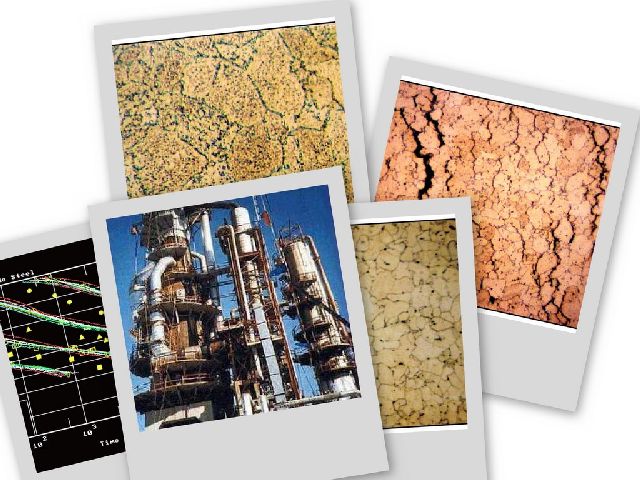

Spheriodisation A useful

technique for assessing service temperatures of carbon and low alloy steel plant

components is to note the degree of spheroidisation of iron and other carbides.

This technique is especially useful when there is doubt about the reliability of

thermocouple measurements.

It

is well known that the amount of spheroidisation is dependent upon both time and

temperature. Toft and Marsden demonstrated that there are basically six stages

of spheroidisation and using a Sherby Dorn type parametric equation, showed that

it was possible to get a reasonable correlation with a "weighted average"

service temperature.

Fortunately, because the creep

rupture life correlates reasonably well with this weighted average, the method

is valuable in monitoring the remanent life of plants.

In-situ surveys can be done using a

surface replica technique.

When assessing steels, the effects

of stress relief which induces some spheroidisation have to be considered.

Furthermore, in the case of low alloy steels containing significant amounts of

chromium and molybdenum, the as-received microstructures can contain significant

amount of massive carbides and bainite which will influence spheroidisation

structures.

|