|

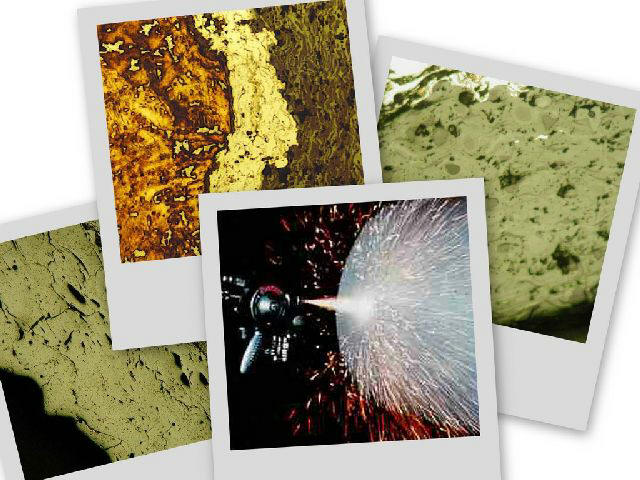

Thermal Spray Coatings

Thermal spray coatings are

most often used for corrosion or erosion/abrasion protection. We have seen them used in

recovery boilers, digesters, and on Yankee dryers. The alloy composition of the layers

required to make up the coating is proprietary and chosen for the intended service

conditions. The method of thermal spray coating application can be by flame, plasma, or

detonation gun, each with slightly different results. The physical properties of the

finished coating are what engineers are most interested in. We recommend the

type of coating depending on application.

In our laboratory, we test

samples of applied coatings , surface hardness, Vickers microhardness of individual

layers, porosity/permeability and alloy segregation. These properties will give us an

idea of how the coating will perform in service. The results of this type of testing are

generally qualitative and require some material engineering judgment to

evaluate. Often we compare potential coating systems using these tests and report our results and

recommendations to the client.

|