|

Magnetic

Particle Inspection

Surface preparation: Less than 0.5mm of paint

Availability: Widely available

Safety implications: Fire hazard - Cable or prod electrodes

Coverage: Area - near surface

Materials: Ferromagnetic materials, e.g. carbon steels

Sensitivity: Minimum detectable flaw size: 1mm high x 5mm long

Theory

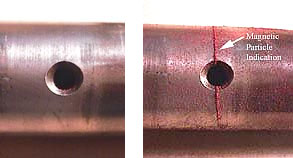

Magnetic particle inspection (MPI) is used for the detection of

surface and near-surface flaws in ferromagnetic materials. A

magnetic field is applied to the specimen, either locally or

overall, using a permanent magnet, electromagnet, flexible

cables or hand-held prods. If the material is sound, most of the

magnetic flux is concentrated below the material’s surface.

However, if a flaw is present, such that it interacts with the

magnetic field, the flux is distorted locally and ‘leaks’ from

the surface of the specimen in the region of the flaw. Fine

magnetic particles, applied to the surface of the specimen, are

attracted to the area of flux leakage, creating a visible

indication of the flaw. The materials commonly used for this

purpose are black iron particles and red or yellow iron oxides.

In some cases, the iron particles are coated with a fluorescent

material enabling them to be viewed under a UV lamp in darkened

conditions. applied to the surface of the specimen, are

attracted to the area of flux leakage, creating a visible

indication of the flaw. The materials commonly used for this

purpose are black iron particles and red or yellow iron oxides.

In some cases, the iron particles are coated with a fluorescent

material enabling them to be viewed under a UV lamp in darkened

conditions.

Magnetic particles are usually applied as a suspension in water

or paraffin. This enables the particles to flow over the surface

and to migrate to any flaws. On hot surfaces, or where

contamination is a concern, dry powders may be used as an

alternative to wet inks. On dark surfaces, a thin layer of white

paint is usually applied, to increase the contrast between the

background and the black magnetic particles. The most sensitive

technique, however, is to use fluorescent particles viewed under

black light.

MPI is particularly sensitive to surface-breaking or

near-surface cracks, even if the crack opening is very narrow.

However, if the crack runs parallel to the magnetic field, there

is little disturbance to the magnetic field and it is unlikely

that the crack will be detected.

For this reason it is

recommended that the inspection surface is magnetised in two

directions at 90° to each other. Alternatively, techniques using

swinging or rotating magnetic fields can be used to ensure that

all orientations of crack are detectable. For this reason it is

recommended that the inspection surface is magnetised in two

directions at 90° to each other. Alternatively, techniques using

swinging or rotating magnetic fields can be used to ensure that

all orientations of crack are detectable.

The method of magnetisation depends on the geometry of the

component and whether or not all or only part of the specimen is

to be magnetised. Permanent magnets are attractive for

in-service inspection, in that they do not need a power supply.

However, they tend only to be used to examine relatively small

areas and have to be pulled from the test surface. Despite

needing their own power supply, electromagnets (yokes) find

widespread application. Their main attraction is that they are

easy to remove (once the current has been switched off) and that

the strength of the magnetic field can be varied. For example,

an AC electromagnet can be used to concentrate the field at the

surface where it is needed. Hand-held electrical prods are

useful in confined spaces. However, they suffer two major

disadvantages that can rule out their use altogether. Firstly,

arc strikes can occur at the prod contact points and these can

damage the specimen surface. Secondly, because the particles

must be applied when the current is on, the inspection becomes a

two-man operation.

In some cases, MPI can leave residual fields which subsequently

interfere with welding repairs. These can be removed by slowly

wiping the surface with an AC yoke.

What will it find?

MPI is used to detect surface-breaking and near-surface flaws in

ferromagnetic materials. It cannot, however, be used to detect

deeply embedded flaws, nor can it be used on non-ferromagnetic

materials, such as aluminium, copper or austenitic stainless

steel.

Application areas

MPI is often used to look for cracking at welded joints and in

areas identified as being susceptible to environmental cracking

(i.e. stress corrosion cracking or hydrogen induced cracking),

fatigue cracking or creep cracking. Wet fluorescent MPI finds

widespread use in looking for environmental damage in the inside

of vessels. Further information on each of these cracking

mechanisms and their significance in piping systems is given in

API 570.

Just as there is a general processing specification for

penetrants, there is one general processing specification for

magnetic particle inspection. The processing specification is

ASTM E-1444 “Standard Practice for Magnetic Particle

Examination”. (This specification replaced MIL-STD-1949.) There

are a number of AMS magnetic particle material specifications

listed in ASTM E-1444. These AMS specifications determine the

requirements for magnetic particle materials. These AMS

(Aerospace Material Specifications) can be purchased from the

Society of Automotive Engineers (SAE).

The list of AMS

specifications referenced in ASTM E-1444 is:

AMS 2641 “Magnetic Particle Inspection Vehicle” Replaced the

military specification DOD F-87935.

AMS 3040 “Magnetic Particle, Non-Fluorescent, Dry Method”

AMS 3041 “Magnetic Particle, Non-Fluorescent, Wet Method, Oil

Vehicle, Ready-to-Use”

AMS 3042 “Magnetic Particle, Non-Fluorescent, Wet Method, Dry

Powder”

AMS 3043 “Magnetic Particles, Non-Fluorescent, Wet Method, Oil

Vehicle, Aerosol Packaged”

AMS 3044 “Magnetic Particles, Fluorescent, Wet Method, Dry

Powder”

AMS 3045 “Magnetic Particles, Fluorescent, Wet Method, Oil

Vehicle, Ready-to-Use”

AMS 3046 “Magnetic Particles, Fluorescent, Wet Method, Oil

Vehicle, Aerosol Packaged”

AS 4792 “Water Conditioning Agents for Aqueous Magnetic Particle

Inspection”

AS 5282 “Tool Steel Ring Standard for Magnetic Particle

Inspection”

AS 5371 “Reference Standards Notched Shims for Magnetic Particle

Inspection”

In order to perform a magnetic particle inspection requiring an

oil bath and fluorescent particles, AMS 2641 “Magnetic Particle

Inspection Vehicle” and AMS 3044 “Magnetic Particles,

Fluorescent, Wet Method, Dry Powder" or AMS 3045 "Magnetic

Particles, Fluorescent, Wet Method, Oil Vehicle, Ready-to-Use”

should be specified to meet the certifying requirements for

magnetic particle inspection for this example.

A magnetic particle specification that is often referenced, is

ASTM E-709 “Guide for Magnetic particle Examination”. This

specification as its title suggests is a tutorial document to

provide additional information on magnetic particle examination.

ASTM E-709 provides additional information on the methods, and

quality control requirements for magnetic particle examination.

The general processing specifications for magnetic particle

inspection is ASTM E-1444 “Standard Practice for Magnetic

Particle Examination”. ASTM E-1444 does use supporting

specifications (ASTM E-709 and AMS Material Specifications to

name a few) for processing parts using the magnetic particle

method. ASTM E-709 is a guideline for magnetic particle

processing and should only be used as a supporting document to

ASTM E-1444.

Back to failure analysis tools

|