|

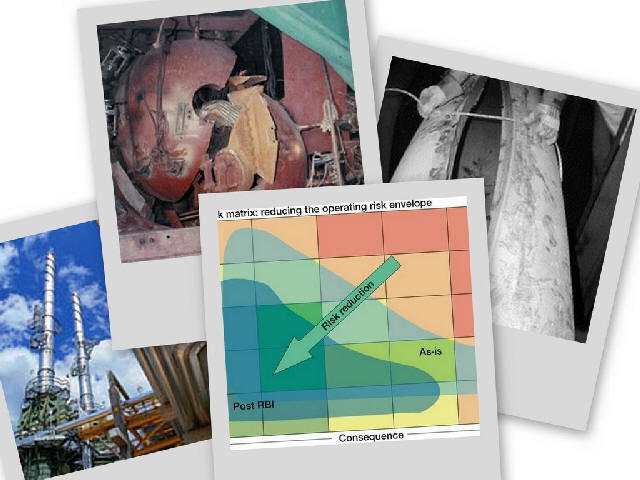

Risk-based

inspection (RBI) uses risk analysis methods to focus tests and inspections on

process equipment in high-risk service so that potential losses in terms of

safety, environmental impacts, equipment damage, and business interruption are

minimized. Its utility is based on the rough premise that 10% of the equipment

in a process contributes 90% of the risk. Consequently, if this 10% of the

equipment can be identified, testing and inspection can be focused on it rather

than low-risk items. This approach is clearly preferable to the usual method of

treating all equipment equally, regardless of its risk contribution.

Based on

the The American Petroleum Institute (API) specification Metserve has developed an RBI

software-approach. The technique looks at both the likelihood of failure as well as the

associated consequence for each piece of equipment. RBI is used to focus

inspections and resources on those equipment items that have the greatest

likelihood and consequence of failure.

|