|

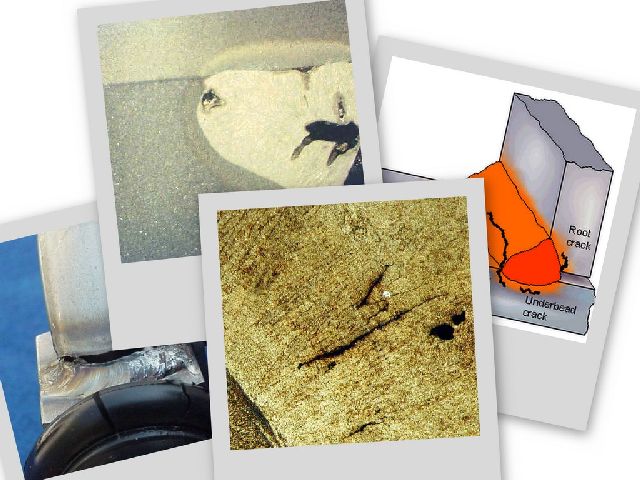

Welding-failures: chance or negligence?

We can help you with understanding your problems

that are plaguing your field welds or shop welds.

Whether you are experiencing problem with MIG (GMAW),

TIG (GTAW), Stick (SMAW), SAW, Brazing or complaints

with weld quality from your customers we can solve your problems.

Here is some of our everyday weld and welding related

metallurgical testing and failure analysis laboratory

services-

Physical Testing

Filler Material Identification

Laboratory Failure Analysis

Scanning Electron Microscope

Impact Test: Charpy & Izod, Tensile Testing ,Bend Test

Metserve metallurgist can solve your -

Welding-failures, service failures, weld defects,

weld joint metallography, discontinuities, burst fractures, corrosion attack,

overheat, crack in welds, wear damage, fatigue cracks, overload, faulty design, metallurgical

failures, wrong material selection, inadequate welding

procedures, joining

questions needing answers: these are some of the items

we are specialists in.

The

problem with Welding-failures is that they happen

without warning, at the worst moment, in the most

damaging way, with most costly repair procedures. That

is common to all failures, probably. What can we learn

from a failure? If we are keen and determined we can

learn how to avoid it next time, how to improve what we

do.

|