Steps for failure

analysis

To interpret a failure

accurately, the analyst has to gather all pertinent facts and

then decide what caused them. To be consistent, the analyst

should develop and follow a logic path that ensures a critical

feature will not be over looked. The following steps should be

taken:

Decide what to do. How detailed an analysis is necessary? Before

starting, try to decide how important the analysis is. If the

failure is relatively insignificant, in cost and inconvenience,

it deserves a cursory analysis; the more detailed steps can be

ignored. But this strategy increases the chance of error. Some

failures deserve a 20-minute analysis with an 80 percent

probability of being correct, but critical failures require true

root cause failure analysis (RCFA), in which no questions are

left unanswered. RCFA may require hundreds of man-hours, but it

guarantees an accurate answer.

Find out what happened. The most important step in solving a

plant failure is to seek answers soon after it happened and talk

to the people involved. Ask for their opinions, because they

know the everyday occurrences at their worksite and their

machinery better than anyone. Ask questions and try to get first

person comments. Do not leave until you have a good

understanding of exactly what happened and the sequence of

events leading up to it.

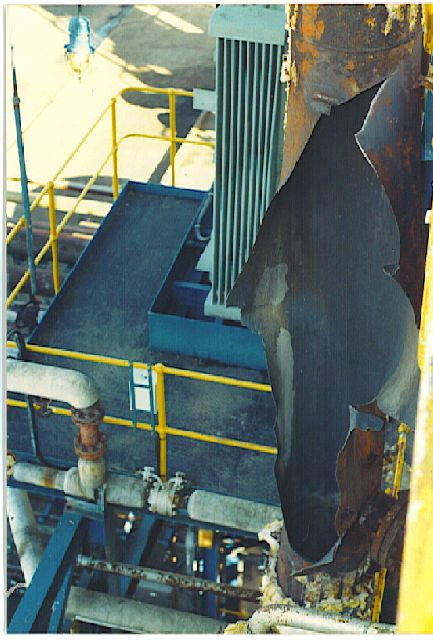

Make a preliminary

investigation. At the site,

examine the broken parts, looking for clues. Do not clean them

yet because cleaning could wash away vital information. Document

the conditions accurately and take photographs from a variety of

angles of both the failed parts and the surroundings.

Gather

background data. What are the

original design and the current operating conditions? While

still at the site, determine the operating conditions; time,

temperatures, amperage, voltage, load, humidity, pressure,

lubricants, materials, operating procedures, shifts, corrosives,

vibration, etc. Compare the difference between actual operating

conditions and design conditions. Look at everything that could

have an effect on machine operation.

Determine what failed. After you leave the site and the

immediate crush of the failure, look at the initial evidence and

decide what failed first—the primary failure—and what secondary

failures resulted from it. Sometimes these decisions are very

difficult because of the size of analysis that is necessary.

Find out what changed. Compare current operating conditions with

those in the past. Has surrounding equipment been altered or

revised?

Examine and analyze the primary failure. Clean the component and

look at it under low-power magnification, 5x to 50x. What does

the failure face look like? From

the failure face, determine the forces that were acting on the

part. Were conditions consistent with the design? With actual

operation? Are there other cracks or suspicious signs in the

area of the failure? Important surfaces should be photographed

and preserved for reference.

Characterize the failed piece and the support material. Perform

hardness test, dye penetrant and ultrasonic examination,

lubricant analysis, alloy analysis, etc. Examine the failed part

and the components around it to understand what they are. Check

to see if the results agree with design conditions.

Conduct detailed

chemical and metallurgical analyses. Sophisticated

chemical and metallurgical techniques may

reveal clues to material weaknesses for minute quantities of

chemical that may cause unusual fractures.

Determine the failure type and the forces that caused it. Review

all the steps listed. Leaving any questions unasked or

unanswered reduces the accuracy of the analysis.

Determine the root causes.

Always ask, "Why did the failure happen in the first place?"

this question usually leads to human factors and management

systems. Typical root causes like "The shaft failed because of

an engineering error" or "The shaft failed because it was not

aligned properly" expose areas where huge advances can be

realized. However, these problems have to be dealt with

differently; people will have to recognize personal errors and

to change the way they think and act.

Laboratory Equipment |