|

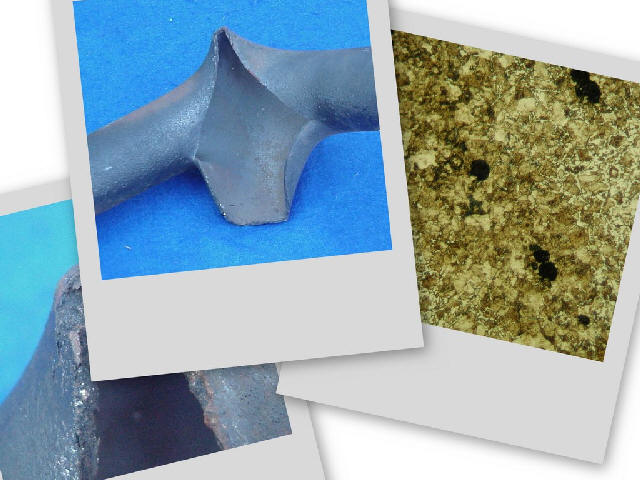

Graphitization

Graphitization can take place in ferritic steels after exposure

to high temperature for extended time, owing to reversion of the

cementite in the pearlite to the more stable graphite phase. It

is a particular form of microstructural degradation that was

formerly observed relatively frequently in petrochemical

components. With the development of more stable Cr Mo steels, it

is not often seen today, but occurs from time to time both in

petrochemical plant and in steam generators in which the

temperature is high and the material is not entirely stable.

Graphitization of

carbon and carbon-molybdenum steel piping during service at

temperatures above 425 °C (800 °F) has caused numerous failures

in steam power plants and refineries. The graphitization

tendency of carbon and carbon-molybdenum steels is increased

when the aluminum content exceeds about 0.025%. Steels

deoxidized with silicon may also be susceptible to

graphitization. Deoxidation with titanium will usually produce

good resistance to graphitization.

Carbon-molybdenum steels

exhibit greater resistance to graphitization than do carbon

steels.

The degree of embrittlement depends on the distribution, size,

and shape of the graphite. The severity of graphitization is

frequently evaluated by bend testing. If graphitization is

detected in its early stages, the material can often be

rehabilitated by normalizing and tempering just below the lower

critical temperature. Steel that has undergone more severe

graphitization cannot be salvaged in this manner; the defective

region must be cut out and re welded, or the section must be

replaced. Carbon and carbon-molybdenum steels can be rendered

less susceptible to graphitization by tempering just below the

lower critical temperature. |